3D scanning is a cutting-edge technology that uses precise laser measurements to capture the shape, appearance, and dimensions of real-world objects. These measurements are then used to create a digital, three-dimensional (3D) model of the object. 3D models created by 3D scanning provide accurate measurements, dimensions, and mounting points

Although 3D scanning is a new technology, 3D models themselves have been around for a long time, and have widespread use in modern industry. For example:

Working with 3D models can speed up product design and prototyping cycles, resulting in more opportunities for quality control, lower development costs, and better finished products.

However, designing a 3D model is a tedious process that must be done by hand using specialized computer-aided design (CAD) software, making it a bottleneck in any industrial process.

3D scanning can revolutionize this process by reducing the time needed to make high-quality models.

3D scanning is a versatile technology, with a wide range of possible uses. Any project that uses 3D models can benefit from 3D scanning.

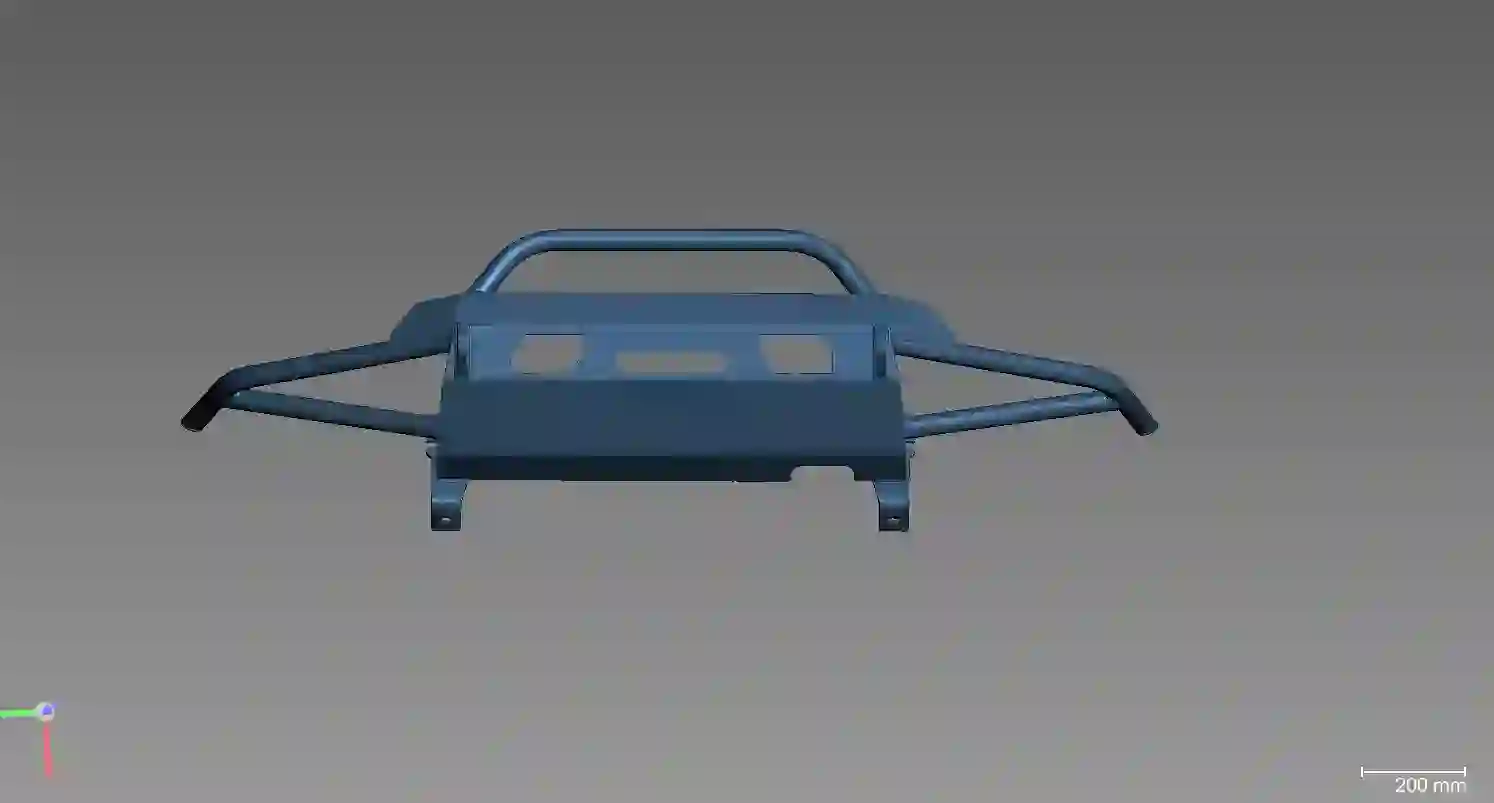

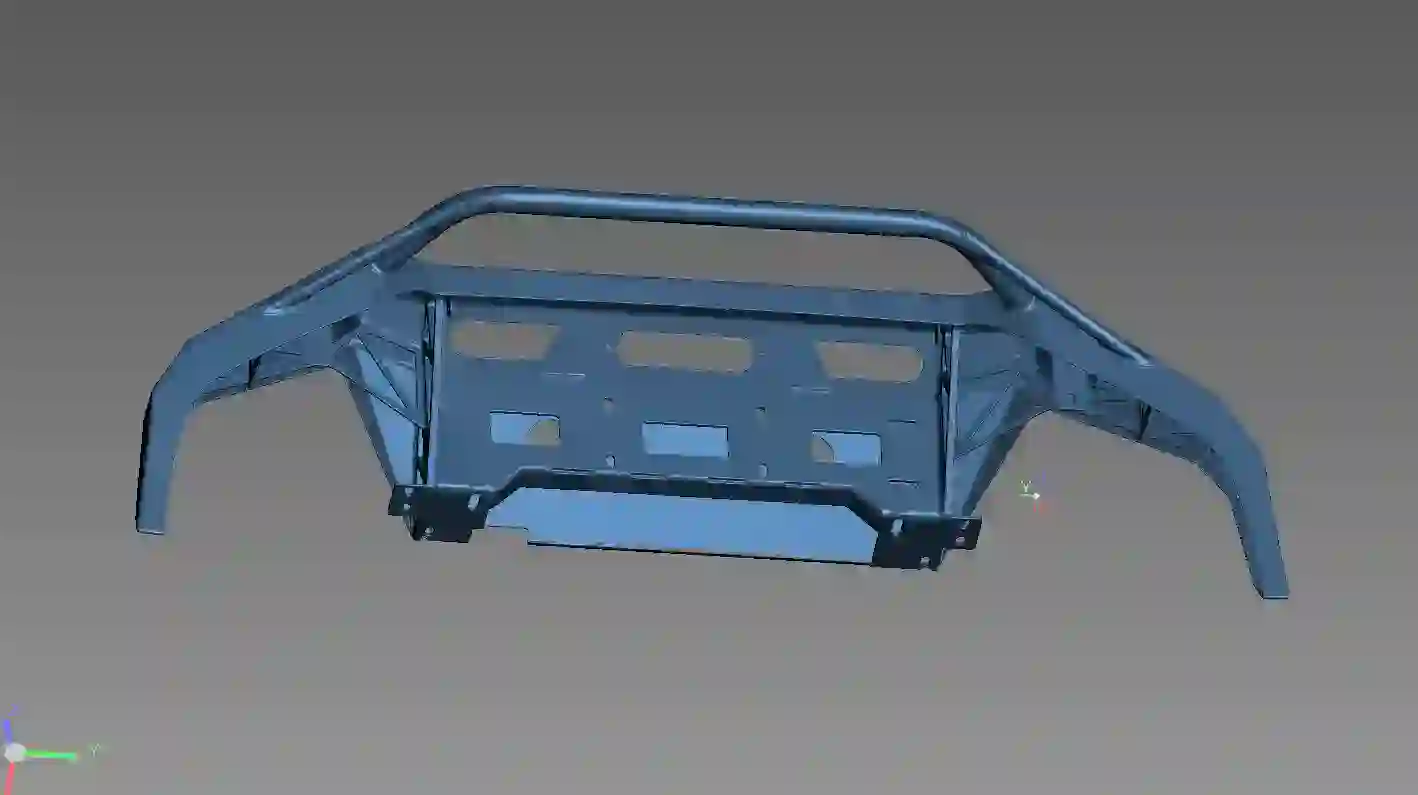

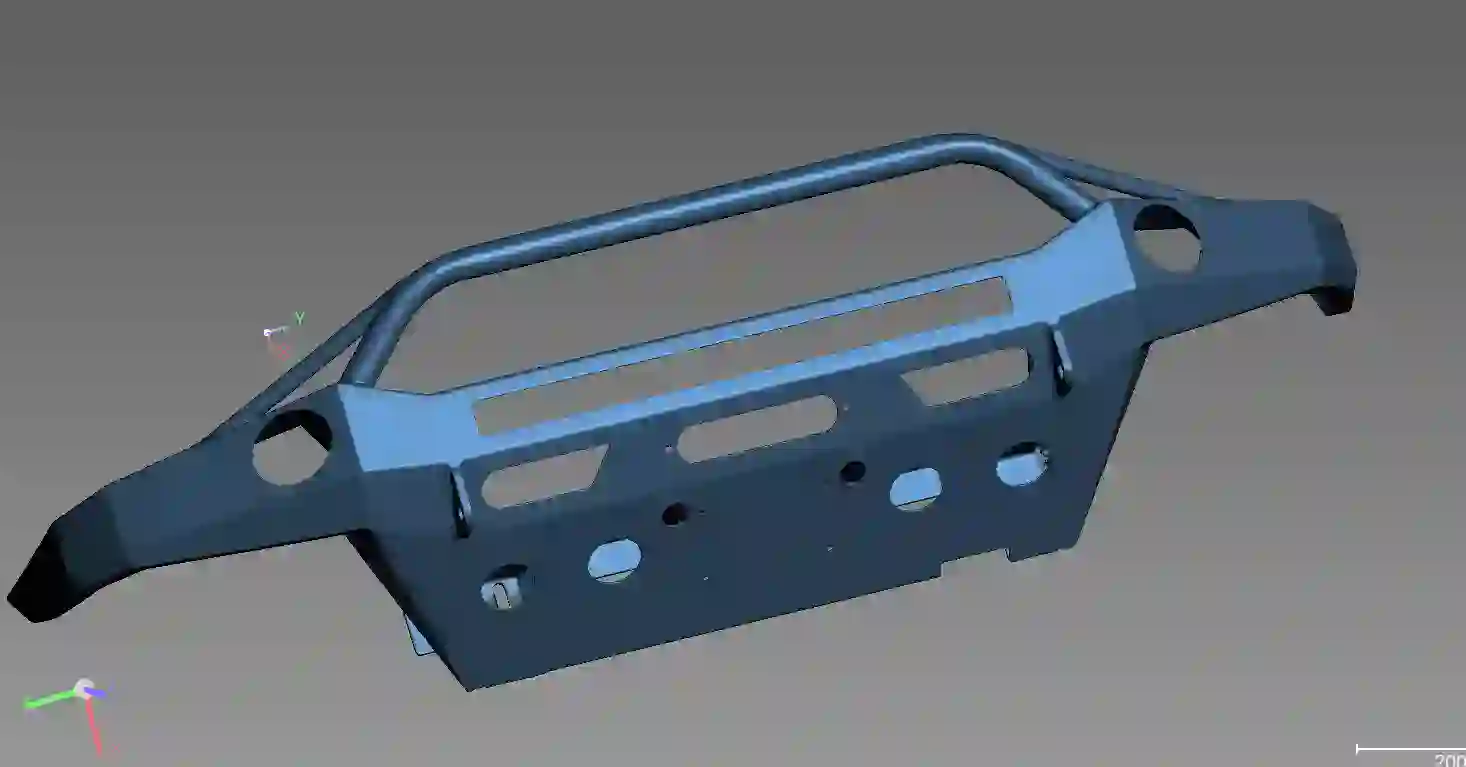

The most direct application is in additive manufacturing, also known as 3D printing. 3D printers use 3D models like blueprints to print a real-life version of the digital 3D model. 3D scanning can be integrated into this industry by rapidly generating high-quality 3D models of real objects. These models can then be refined or enhanced using CAD software before being printed, facilitating the creation of accurate, detailed, and complex parts.

3D scanning is also useful for producing bespoke parts, rapid prototyping, and small-batch manufacturing.

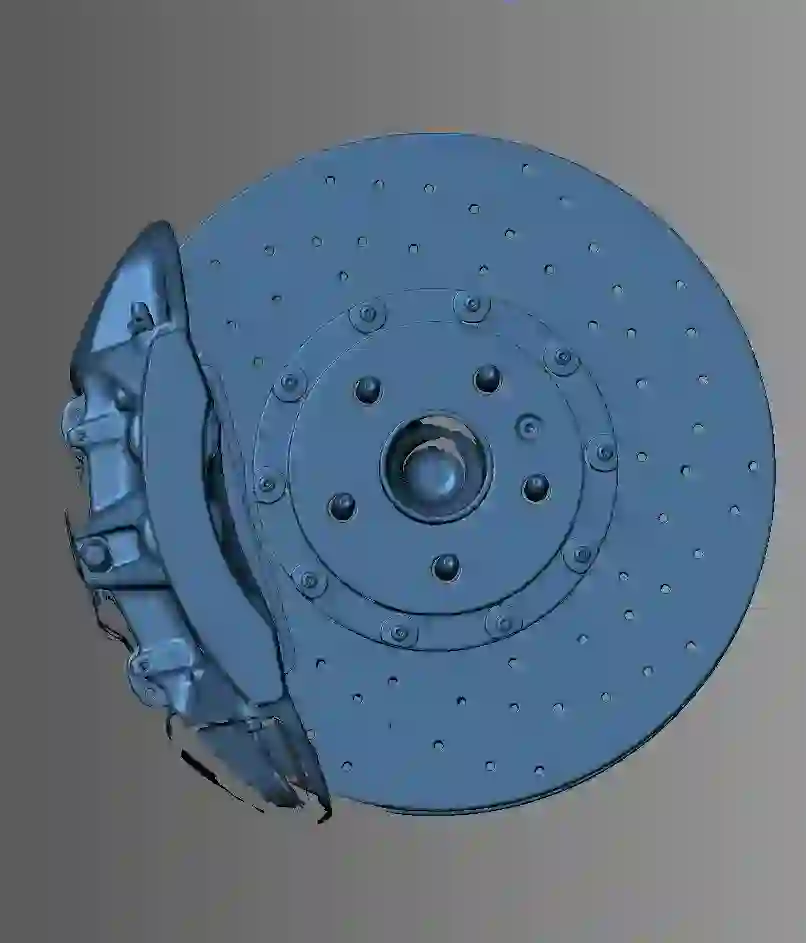

There are also exciting applications for reverse engineering, which involves deconstructing an existing product to understand its design, structure, and functionality. 3D scanning allows companies to easily analyze and replicate products, improve upon existing designs, or ensure compatibility with other components.

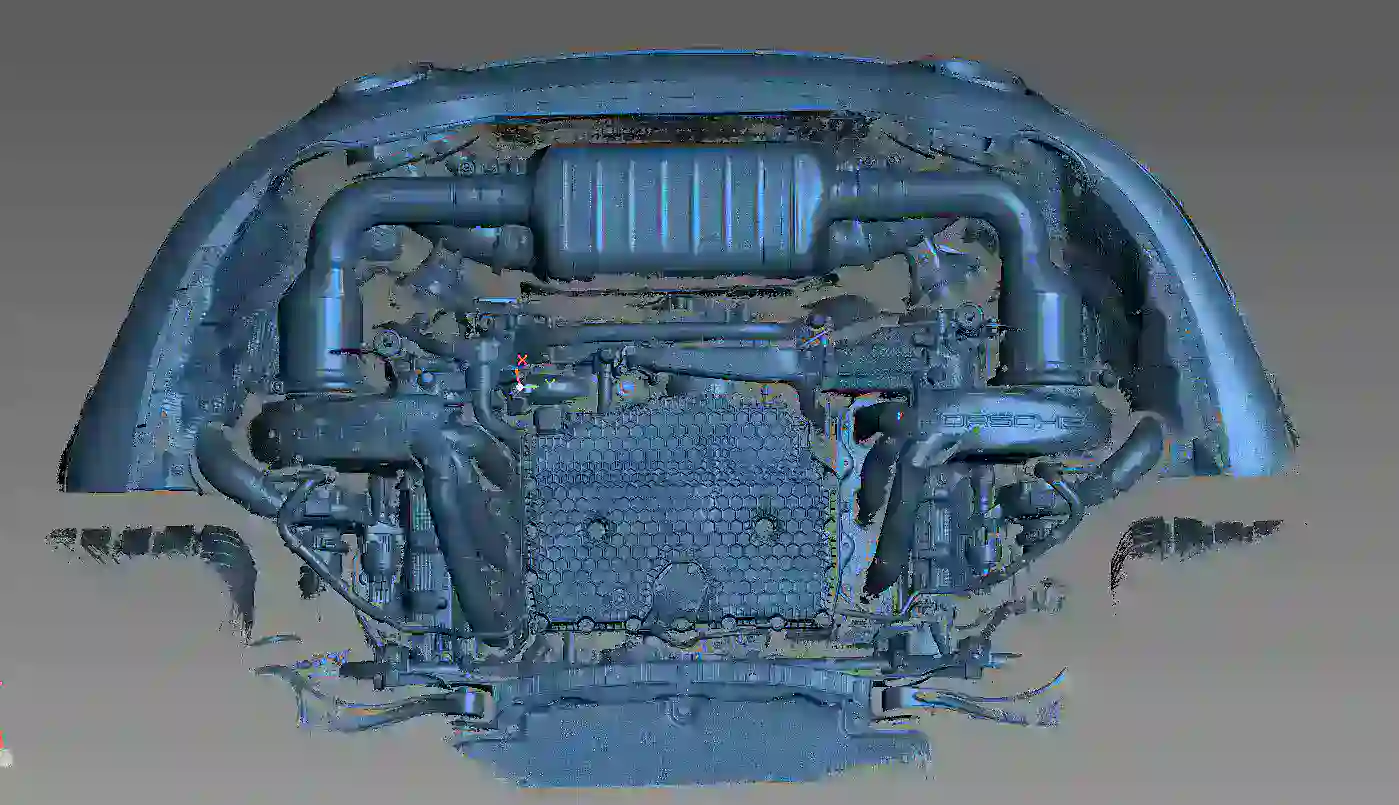

1st photo - A Porsche 997 disc brake. 2nd photo - The 3D model we made of the disc brake. 3rd photo - A custom rim designed around the 3D model. Photos courtesy of Exhibitions of Speed

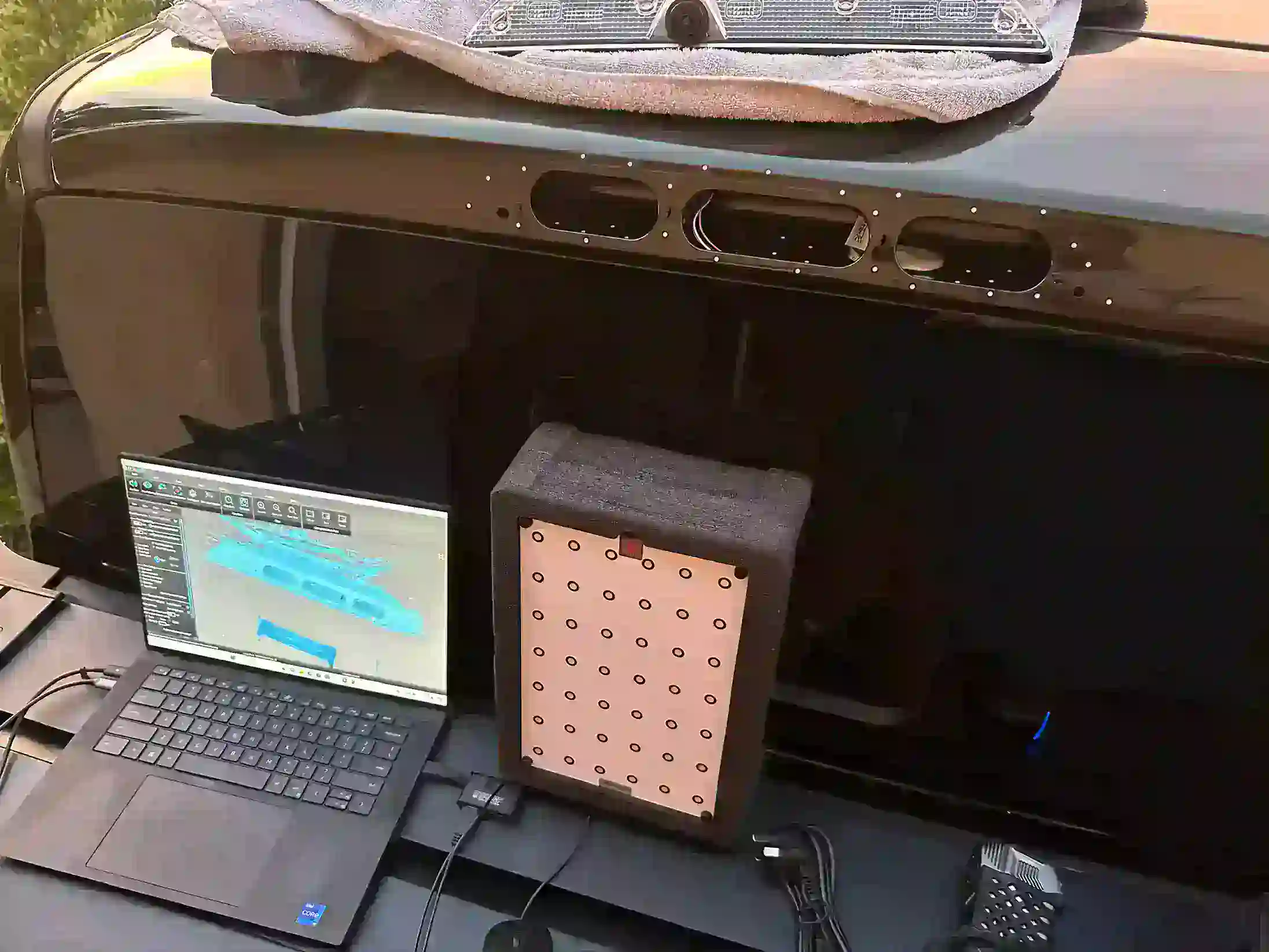

Using the latest in handheld laser scanning technology, we bounce laser beams off an item's surface to analyze its features and generate a detailed, three-dimensional model, which we save as an STL file.

The STL file can be used in the CAD software program of your choice. You can use your 3D model for a variety of purposes, ranging from 3D printing prototypes, modeling designs, or running simulations.

Using precision lasers to measure an item ensures that every detail, no matter how minute, is accurately captured and represented in the digital model.

We can capture intricate systems or single pieces. Our models are accurate up to .02 thousandths on parts as small as a bolt, or as large as a vehicle.

No matter the size or complexity, we can create a high-resolution 3D model of it.

Our laser scanning service is fast, efficient, and cost-effective. Getting started is simple. Here's how.

Contact us by phone or email. Give us a detailed description of the item you need scanned.

We'll evaluate the difficulty of scanning your item, and give you an affordable, flat-rate quote.

Mail us your item. Once we receive your item, we'll have another phone call with you, to finalize the scanning process and make sure all the component's important features are included in the scan.

We perform the scan of your item and create an STL file with a 3D model based on the scan.

As soon as we receive your payment, we'll send you the STL file for review. Once you approve, we'll mail your component back to you in the original packaging it came in.

If you can't mail us your item, we can come to you. We offer the option to arrange travel to your location for on-site 3D scanning at an additional cost. Please contact us for more details and to discuss your specific needs.

To request a quote, please contact us using the information below.

We need a detailed description of the component you need scanned in order to give you an accurate quote. Be sure to include a phone number, so that we can reach out to discuss your needs in more detail.

We look forward to hearing from you!